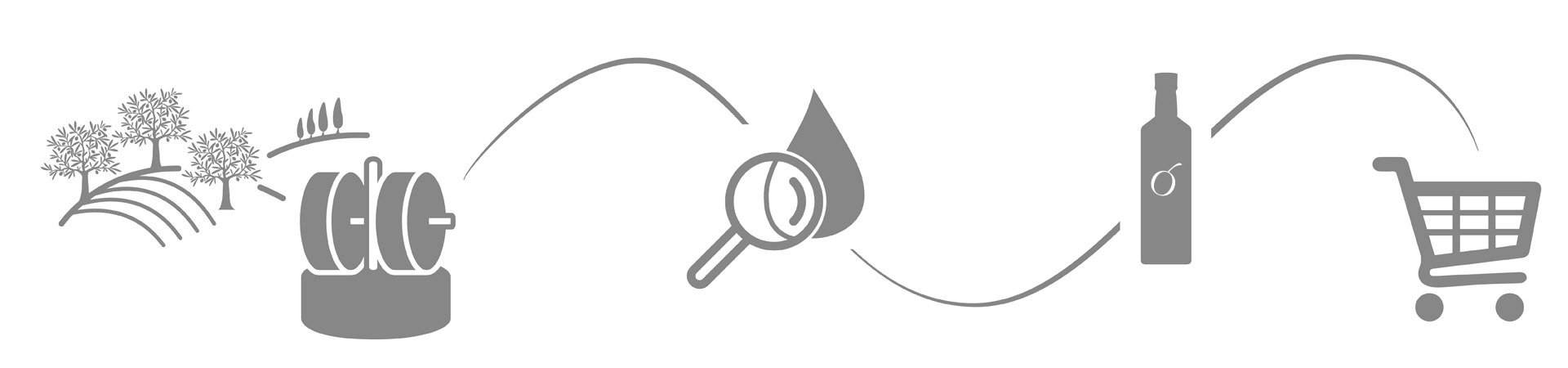

PrimOli checks the compliance of bulk oil ready for bottling by means of a detailed Control Plan designed to ensure compliance with relevant EU quality, authenticity and food safety regulations .

Quality checks for each stage of the bottling process are listed in the Technical Specifications and need to be adhered to by all suppliers. Detailed instructions on how to produce and label single bottles are set out in Technical Files created by PrimOli for each product.

In accordance to a scheduled sampling plan, end products undergo analytical tests to ensure that all dynamic parameters are within the applicable Standard Specifications limits. These samples also undergo a sensory evaluation of their organoleptic profile.

PrimOli uses a fully integrated and highly automated logistics solution to manage the entire supply chain, from planning outsourced production to the grouping of end products in one single warehouse as well as delivery to agents or retailers.

© 2017 Primoli – P.Iva 01165110998 – Molo Ponte Morosini, 49/7 – 16126 Genova GE – +39 010 2530024